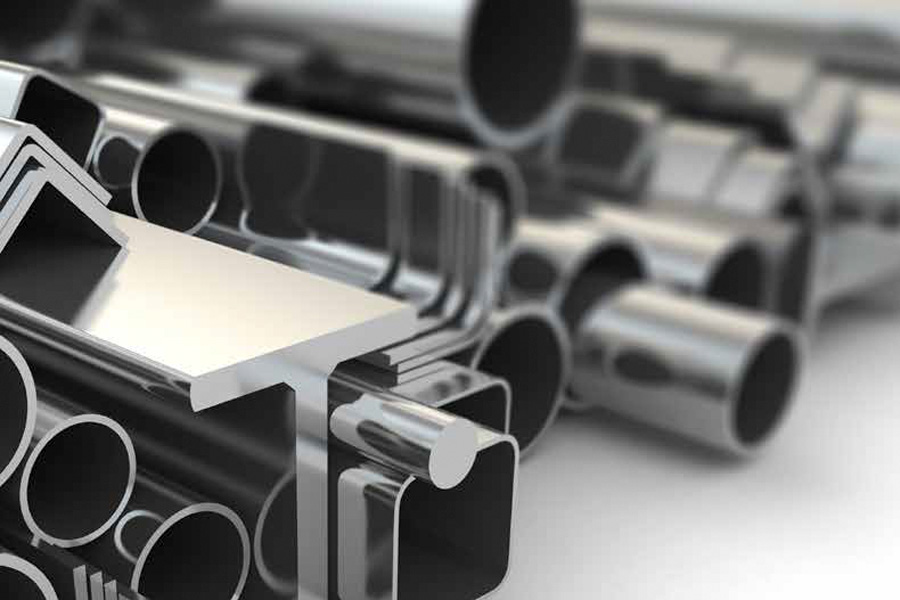

We provide a comprehensive range of flat, rolled and extruded aluminium products to meet your needs.

Our range of aluminium products includes standard and customer-specific extrusions.

We provide a comprehensive range of flat, rolled and extruded aluminium products to meet your needs.

Our range of aluminium products includes standard and customer-specific extrusions.

We provide a comprehensive range of flat, rolled and extruded aluminium products to meet your needs.

Our range of aluminium products includes standard and customer-specific extrusions.

Product Range

Our branches carry a wide range of aluminium products which are tailored to local market requirements. Please find our Product Catalogues below.

Service

We pride ourselves on industry-leading service. We aim to always have key products in stock and be able to deliver them quickly, allowing you to complete your project on-time.

Location

We have a large branch network across New Zealand and Australia. Being close to our customers is at the heart of everything we do.

Would you like to know more?

Vulcan Ullrich Aluminium Extrusion Catalogue

Please find our New Zealand Extrusion Catalogue below.

If you have any queries relating to Vulcan Ullrich Aluminium products, please contact your local branch.

Vulcan Ullrich Aluminium Product Catalogues

Please find our Product Catalogues below.

If you have any queries relating to Vulcan Ullrich Aluminium products, please contact your local branch.